The M1 Abrams Main Battle Tank (MBT) is the namesake of the late General Creighton W. Abrams, former Army Chief of Staff and commander of the 37th Armored Battalion. It is the backbone of the armored forces of the United States military, and several of US allies as well. The purpose of this vehicle is to provide mobile firepower for armored formations of sufficient capability to successfully close with and destroy any opposing armored fighting vehicle in the world, while providing protection for it's crew in any conceivable combat environment. It is capable of engaging the enemy in any weather, day or night on the multi-dimensional, non-linear battlefield using its firepower, manuever, and shock effect. The Abrams Tank System synchronizes its high tempo, distributed manuever via its digitized situational awareness and the fusion of onboard and remote battlefield sensors.

Production of M1A1 tanks for the US Army is complete. Over 8,800 M1 and M1A1 tanks have been produced for the US Army and Marine Corps, and the armies of Egypt, Saudi Arabia and Kuwait. Production of new M1A1 and M1A2 Abrams tanks is in its final phase for Foreign Military Sales. Three versions of the Abrams tank are currently in service the original M1 model, dating from the early 1980s, and two newer versions, designated M1A1 and M1A2. The M1A1 series, produced from 1985 through 1993, replaced the M1’s 105mm main gun with a 120mm gun and incorporated numerous other enhancements, including an improved suspension, a new turret, increased armor protection, and a nuclear-chemical-biological protection system. The newer M1A2 series includes all of the M1A1 features plus a commander’s independent thermal viewer, an independent commander’s weapon station, position navigation equipment, and a digital data bus and radio interface unit providing a common picture among M1A2s on the battlefield.

In lieu of new production, the Army is upgrading approximately 1,000 older M1 tanks to the M1A2 configuration. The Army also initiated a modification program for the M1A2 to enhance its digital command and control capabilities and to add the second generation forward looking infrared (FLIR) sights to improve the tank's fightability and lethality during limited visibility. This system enhancement program will be fielded in the 2000 time frame concurrently with the M2A3 Bradley and other advanced digital systems. The initial M1A2 fielding to the First Calvary Division, Ft. Hood, TX, is underway. The Army will continue to field M1A2s to the CONUS contingency corps and other first to fight units into the next decade.

M1/IPM1 M1A1 M1A2 Length: 32.04 FT 32.25 FT 32.25 FT Width: 12.0 FT 12.0 FT 12.0 FT Height: 7.79 FT 8.0 FT 8.0 FT Top Speed: 45.0 MPH 41.5 MPH 41.5 MPH Weight: 60 TONS 67.6 TONS 68.7 TONS Armament: 105 MM 120 MM 120 MM Crew: 4 4 4 The M1 series tank is equipped with a 1500 horsepower Lycoming Textron gas turbine engine coupled to an Allison hydrokenetic transmission with four forward and two reverse gears. It's tactical crusing range is approximately 275 miles. Despite it's weight, the M1 can attain a top speed of nearly 45 miles per hour. The main armament is a 120mm smooth bore cannon, which replaced the 105mm gun on the initial M1 version. It has day/night fire on the move capability which is provided by a laser range finder, thermal imaging night sight, optical day sight, and a digital ballistic computer. Both the fuel and ammunition are compartmented to enhance survivability. The hull and turret are protected by advanced armor similar to the Chobam armor developed by the British Ministry of Defense. When required, the Abrams may be fitted with "reactive armor" to thwart armor-defeating munitions.

Although fielded in 1980, the Abrams remained untested for over 10 years. When Iraq invaded Kuwait in August 1990, there were concerns that the Abrams would fall victim to the sand and long months of continuous operation without the luxury of peacetime maintenance facilities. There were also doubts about the combat survivability of the extensive turret electronics. Immediately following President Bush's decision to commit US forces to the Gulf region in defense of Kuwait and Saudi Arabia, American armored units began the difficult process of relocating to the threatened area. Due to the shear size and weight of the Abrams, the C-5 Galaxy, the largest cargo aircraft in the US Air Force inventory, was only able to handle one tank at a time. This meant that nearly all of the Abrams tanks deployed in the Gulf War were shipped by cargo ship. Although slow in coming, the arrival of the Abrams was much welcomed by Allied forces, as it is capable of defeating any tank in the Iraqi inventory.The Iraqi Army had a considerable array of tanks, mostly purchased from the former Soviet Union. Chief among these were about 500 T-72's. These modern Soviet tanks were armed with an excellent 125mm smoothbore weapon and had many of the same advanced features found on the Abrams. Despite it's advanced design, the T-72 proved to be inferior to the M1A1's deployed during the Gulf War, and compared more closely with the older M60A3 tanks used there by the US Marine Corps. In addition, Iraq had a number of earlier Soviet models: perhaps as many as 1,600 T-62 and about 700 T-54, both of which were developed in the 1960's. These tanks were widely regarded as clearly inferior to the Abrams, but were expected to be highly reliable mechanically. The Gulf War provided military tacticians with an opportunity to evaluate developments in tank design that had not been available since World War II.

In his book "Desert Victory - The War for Kuwait", author Norman Friedman writes that "The U.S. Army in Saudi Arabia probably had about 1,900 M1A1 tanks. Its ability to fire reliably when moving at speed over rough ground (because of the stabilized gun mount) gave it a capability that proved valuable in the Gulf. The Abrams tank also has… vision devices that proved effective not only at night, but also in the dust and smoke of Kuwaiti daytime. On average, an Abrams outranged an Iraqi tank by about 1,000 meters." The actual numbers of Abrams M1 and M1A1 tanks deployed to the Gulf War (according to official DOD sources) are as follows: A total of 1,848 M1A1 and M1A1 "Heavy Armor" (or HA) tanks were deployed between the US Army and Marine Corp (who fielded 16 M1A1's and 60 M1A1(HA) tanks).

As the Gulf War shifted pace from Operation Desert Shield to Operation Desert Storm, and the preparatory bombardment lifted, U.S. Abrams tanks spearheaded the attack on Iraqi fortifications and engaged enemy tanks whenever and wherever possible. Just as they had done in the Iran-Iraq War, the Iraqi Army used it's tanks as fixed anti-tank and artillery pieces, digging them into the ground to reduce target signature. However, this also prevented their quick movement and Allied air power smashed nearly 50% of Iraq's tank threat before Allied armor had moved across the border. After that the Abrams tanks quickly destroyed a number of Iraqi tanks that did manage to go mobile.

The Abrams' thermal sights were unhampered by the clouds of thick black smoke over the battlefield that were the result of burning Kuwaiti oil wells. In fact many Gunners relied on their "night" sights in full daylight. Such was not the case with the sights in the Iraqi tanks, which were being hit from units they could not even see. Concerns about the M1A1's range were eliminated by a massive resupply operation that will be studied for years as a model of tactical efficiency.

During the Gulf War only 18 Abrams tanks were taken out of service due to battle damage: nine were permanent losses, and another nine suffered repairable damage, mostly from mines. Not a single Abrams crewman was lost in the conflict. There were few reports of mechanical failure. US armor commanders maintained an unprecedented 90% operational readiness for their Abrams Main Battle Tanks.

See also: M1 Mine Clearing Blade System.

Specifications

M1 / IPM1 M1A1 M1A2 Manufacturer General Dynamics (Land Systems Division) Crew 4: Commander, Gunner, Loader & Driver Weight 60 Tons 63 Tons 69.54 Tons Length (Gun Forward) 384.5 inches 387 inches Turret Height 93.5 inches Width 143.8 inches 144 inches Ground Clearance 19 inches Ground Pressure 13.1 PSI 13.8 PSI 15.4 PSI Obstacle Crossing 49 inches 42 inches Vertical Trench 9 Feet Power plant AGT-1500 turbine engine Power Rating 1500 HP Power to Weight Ratio 25 hp/ton 23.8 hp/ton 21.6 hp/ton Hydro Kinetic Transmission 4 Speed Forward

2 Speed ReverseSpeed - Maximum 45 mph (Governed) 42 mph (Governed) Speed - Cross Country 30 mph Speed - 10% Slope 20 mph 17 mph Speed - 60% Slope 4.5 mph 4.1 mph Acceleration

(0 to 20 mph)7 Seconds 7.2 Seconds Cruising Range 275 Miles 265 Miles Main Armament 105mm M68A1

Rifled Cannon120mm M256

Smooth Bore CannonCommander's Weapon .50 Cal M2 Machinegun Coaxial Weapon 7.62 M240 Machinegun Loader's Weapon 7.62 M240 Machinegun on Skate Mount NBC System 200 SCFM - CleanCooled Air Inventory 403 USMC Unit Replacement Cost $4,300,000 M1 / IPM1 Abrams Main Battle Tank

Designed in the 1970's by the Land Systems Division of the General Dynamics Corporation in response to the U.S. Army's MBT-70 program, the first M1 rolled off the assembly line in 1978. After two years of acceptance trials, the first of these vehicles was delivered to the US Army on February 28, 1980. By 1985, evaluations of field service had prompted the first modification requests, and production shifted to the M1A1. The first M1A1's were delivered to units in August of 1985. The Army has converted 368 older M1s to M1A2s. An additional 580 M1s are being upgraded to A2s under a five-year contract awarded in FY1996, with a total of 998 M1 upgrades planned. In 1999 the Army began upgrading M1s to the M1A2 System Enhancement Program (SEP) configuration. The SEP embeds digitization capabilities inside the Abrams’ electronic architecture, eliminating the requirement for electronic appliques.

M1A1 Abrams Main Battle Tank

The M1A1 is an improved version of the M1 Main Battle Tank (MBT). It includes a 120mm smoothbore main gun, an NBC overpressure protection system, and an improved armor package. This tank significantly increases the capabilities of the Fleet Marine Forces across the full spectrum of conflict in the near and midterm. The M1A1 Tank, in addition to the improved armor, 120mm smoothbore gun and the NBC overpressure system, has a Deep Water Fording Kit (DWFK), a Position Location Reporting Systems (PLRS), enhanced ship tiedowns, Digital Electronic Control Unit (DECU) (which allows significant fuel savings),and Battlefield Override.

The main weapon of the M1A1 is the M256 120mm smoothbore cannon, designed by the Rheinmetall Corporation of Germany. Engagement ranges approaching 4000 meters were successfully demonstrated during Operation Desert Storm. The primary armor-defeating ammunition of this weapon is the armor-piercing, fin-stabilized, discarding sabot (APDS-FS) round, which features a depleted uranium penetrators. Depleted uranium has density two and a half times greater than steel and provides high penetration characteristics. Several other types of ammunition are available as well. It is reliable, deadly accurate and has a "hit/kill ratio" that equals or surpasses any main battle tank armament in the world.

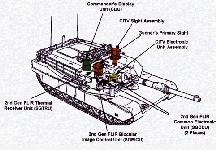

As with virtually every tank every fielded by the US, the familiar .50 caliber Browning M2 Heavy Barrel machine gun - the "Ma Duce" - is located in a powered mount at the Commander's station and is equipped with a x3 magnification sight. The Loader is provided with a 7.62mm M240 machine gun, and another M240 is mounted in-line with the main gun of the tank ("coaxially"). It is in a fixed mount and is aimed with the main gun to suppress enemy ground troops. The layout of the Abrams follows classic tank design and accommodates a crew of four: Commander, Gunner, Loader and Driver. The Commander and Gunner are seated on the right side of the turret. The Loader is seated on the left side of the turret, and the Driver is seated at the center front of the hull. The Commander's station is equipped with six periscopes which provide all round 360 degree view. The Independent Thermal Viewer (ITV) from Texas Instruments provides him with independent, stabilized day and night vision with a 360 degree view, automatic sector scanning, automatic target cueing of the Gunner's sight with no need for verbal communication, and a complete back-up fire control system - the Commander is capable of firing the main gun independent of the Gunner. The Gunner's Primary Sight-Line of Sight (GPS-LOS), was developed by the Electro-Optical Systems Division of Hughes Aircraft Company. The night vision Thermal Imaging System (TIS), also from Hughes, creates an image based on the differences of heat radiated by objects in the field of view. The thermal image is displayed in the eyepiece of the Gunner's sight together with the range measurement to within 10 meters of accuracy, from a Hughes laser range finder, which is integrated into all of the fire control systems. The Abrams also has an onboard digital fire control computer. Range data from the laser rangefinder is transferred directly to the fire control computer, which automatically calculates the fire control solution. The data includes 1) the lead angle measurement, 2) the bend of the gun measured by the muzzle reference system of the main armament, 3) wind velocity measurement from a wind sensor on the roof of the turret and 4) the data from a pendulum static cant sensor located at the center of the turret roof. The Gunner or Commander manually inputs the data on the ammunition type and temperature, and the barometric pressure and the weapon is prepared for engagement. The Loader's station is located on the left side of the turret and has no special fire control equipment. The Driver's station is located at the center front of the hull. The Driver is in a semi-reclined position when his hatch is closed, as it must be whenever the vehicle is in operation. His station is equipped with a standard array of gages and monitors reflecting the condition of vehicle fluid levels, batteries and electrical equipment. The Driver has either three observation periscopes or two periscopes on either side and a central image intensifying ("Starlight") periscope for night vision. The periscopes provide 120 degrees field of view. The Driver's night vision equipment enables the tank to maneuver at normal daytime driving speeds in darkness and in poor visibility conditions such as in the dust and smoke encountered on the battlefield. The turret is fitted with two six-barreled M250 smoke grenade launchers, one on each side of the main gun. The standard smoke grenade contains a phosphors compound that masks thermal signature of the vehicle to the enemy. A smoke screen can also be laid by an engine operated system.An improvement program will eventually upgrade all M1A1 tanks with steel encased depleted uranium armor, which has a density at least two-and-a-half times greater than steel. The depleted uranium armor will raise the total weight of the Abrams tank to 65 tons, but offers vastly improved protection in the bargain.

The stowage for the main armament ammunition is in armored ammunition boxes behind sliding armor doors. Armor bulkheads separate the crew compartment from the fuel tanks. The tank is equipped with an automatic Halon fire extinguishing system. This system automatically activates within 2 milliseconds of either a flash or a fire within the various compartments of the vehicle. The top panels of the tank are designed to blow outwards in the event of penetration by a HEAT projectile.

Nuclear, Biological and Chemical (NBC) warfare protection is provided by an overpressure clean-air conditioning air system, a radiological warning system, and a chemical agent detector. The crew are individually equipped with protective suits and masks.

The Marine Corps has fielded the M1A1 Common Tank to replace the aging M60A1 Rise/Passive tank. The M60 has reached the end of its service life and lacks the capability to survive and to defeat the threats expected to be encountered on the modern battlefield. During Operation Desert Shield/Storm, the Marine Corps borrowed 60 M1A1s (called the M1A1 Heavy Armor) from the US Army. There were also 16 Marine Corps M1A1 Tanks delivered on an accelerated schedule for employment during the operation. This total of 76 M1A1 tanks was employed by 2d Tank Battalion and elements of 4th Tank Battalion. The M1A1 tanks saw immediate action during the I Marine Expeditionary Force (IMEF) drive through the burning Kuwaiti oil fields. All loaned tanks were returned to the US Army after Desert Storm.

Due to unique Marine Corps amphibious requirements, and the need for both supportability and interoperability between the Marine Corps and the US Army, the two services agreed to jointly produce the M1A1 Main Battle Tank. The M1A1 MBT has the capability to conduct operations ashore. It is compatible with all US Navy amphibious ships and craft (to include the LCAC) and Maritime Prepositioning Ships (MPS). The USMC completed fielding of all tanks, to include active, reserve, MPS, and depot maintenance float (DMF) during FY 96.

In 1995 the 26th MEU became the first amphibiously deployed unit to carry the M1A1. This added some complication to the logistics of the unit due to the tank's weight. Topping the scales at over 68 tons the vehicle requires special care during amphibious operations. One tank can be carried at a time on an Air Cushioned Landing Craft (LCAC), two on a Landing Craft Utility (LCU), but only during fairly calm seas. For operations with the Marine Corps, tanks have been equipped with special fording systems. These modifications include extended air intake and exhaust tubes that allow the vehicles to cross rivers and shallow waters such as the surf zones that Marines operate in.

The M1A1 Abrams Tank Firepower Enhancement Program (FEP), a Marine Corps Systems Command initiative, is intended to increase the all weather, day and night target acquisition and engagement ranges and provide a far target location capability for the M1A1 Tank. The FEP system will include a scope of work that entails a suite of upgrades for the M1A1 Tank. These upgrades include a second-generation thermal sight and a north finding/target locating capability. The system will increase the tank crew's ability to detect, recognize, identify and accurately locate targets.M1A1D Abrams Main Battle Tank

The M1A1 fleet remains the majority of the Armor Force. The M1A1D is a digitized M1A1 that provides improved situational awareness and far target designate capability. The installation of a digital appliqué command and control package on the M1A1 is necessary to achieve Force XXI required capabilities. Another planned improvement is replacing the analog Turret Network Box (TNB) and Hull Network Box (HNB) with new digital units to eliminate the associated obsolescence problems and to allow the introduction of a built-in-test (BIT) capability to support the Force XXI maintenance structure. Digital TNBs and HNBs also allow future electronic growth by providing unpopulated VME card slots.In the survivability area the Army is working to develop and field a contingency armor package that is thin and lightweight, but with a high level of protection. These armor packages can be applied to either the side or front of Abrams tanks to provide additional protection as required by the mission. The Army is also seeking to fundo resource upgrades to the M1A1 fire control system with the same 2nd Gen FLIR package on the M1A2.

M1A2 Abrams Main Battle Tank

The mission of the M1A2 Abrams tank is to close with and destroy enemy forces using firepower, maneuver, and shock effect. The M1A2 is being fielded to armor battalions and cavalry squadrons of the heavy force. In lieu of new production, the Army is upgrading approximately 1,000 older M1 tanks to the M1A2 configuration. During the Army’s current M1A2 procurement program about 1,000 older, less capable M1 series tanks will be upgraded to the M1A2 configuration and fielded to the active forces. There is currently no plan to field the M1A2 to the ARNG. The Army has procured 62 new tanks in the A2 configuration and as of early 1997 completed the conversion of 368 older M1s to M1A2s. An additional 580 M1s are being upgraded to A2s under a five-year contract awarded in FY 1996, with a total of 998 M1 upgrades planned. In FY 1999, the Army will begin upgrading M1s to the M1A2 System Enhancement Program (SEP) configuration. This sensor also will be added to older M1A2s starting in FY 2001. When the SEP enters production, the Army will have a total of 627 M1A2s, all of which will eventually be converted to the SEP configuration. Further M1A2 improvements, called the System Enhancement Program (SEP), are underway to enhance the tank's digital command and control capabilities and to to improve the tank’s fightability and lethality. The M1A2 SEP (System Enhancement Package), is the digital battlefield centerpiece for Army XXI. It is the heavy force vehicle that will lead Armor into the next century and transition the close combat mission to the Future Combat System (FCS). The M1A2 SEP is an improved version of the M1A2. It contains numerous improvements in command and control, lethality and reliability. M1A2 SEP is in final operational testing, and scheduled to start fielding in 2000. M1A2 SEP tanks are scheduled to begin fielding in 3QFY00. The M1A2 System Enhanced Program (SEP) is an upgrade to the computer core that is the essence of the M1A2 tank. The SEP upgrade includes improved processors, color and high resolution flat panel displays, increased memory capacity, user friendly Soldier Machine Interface (SMI) and an open operating system that will allow for future growth. Major improvements include the integration of the Second Generation Forward Looking Infared (2nd Gen FLIR) sight, the Under Armor Auxiliary Power Unit (UAAPU) and a Thermal Management System (TMS).The 2nd Generation Forward Looking InfraRed sighting system (2nd Gen FLIR) will replace the existing Thermal Image System (TIS) and the Commander's Independent Thermal Viewer. The incorporation of 2nd Gen FLIR into the M1A2 tank will require replacement of all 1st Gen FLIR components. From the warfighter perspective, this is one of the key improvements on the SEP. The 2nd Gen FLIR is a fully integrated engagement-sighting system designed to provide the gunner and tank commander with significantly improved day and night target acquisition and engagement capability. This system allows 70% better acquisition, 45% quicker firing and greater accuracy. In addition, a gain of 30% greater range for target acquisition and identification will increase lethality and lessen fratricide. The Commander’s Independent Thermal Viewer (CITV) provides a hunter killer capability. The 2nd GEN FLIR is a variable power sighting system ranging from 3 or 6 power (wide field of view) for target acquisition and 13, 25 or 50 power (narrow field of view) for engaging targets at appropriate range.

The UAAPU consist of a turbine engine, a generator, and a hydraulic pump. The generator is capable of producing 6 Kilowatts of electrical power at 214 Amps, 28 vdc, and the hydraulic pump is capable of delivering 10 Kilowatts of hydraulic power. The UAAPU can meet the electrical and hydraulic power to operate all electronic and hydraulic components used during mounted surveilance operations and charge the tank's main batteries. The UAAPU will reduce Operational and Support cost by utilizing the same fuel as the tank at a reduced rate of 3-5 gallons per operational hour. The UAAPU is mounted on the left rear sponson fuel cell area and weighs 510 pounds.

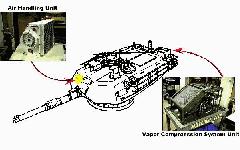

Another improvement in the M1A2 SEP is the Thermal Management System (TMS) which keeps the temperature within the crew compartment under 95 degrees and the touch temperature of electronic units under 125 degrees during extreme conditions. By reducing the temperature in the crew compartment for the crew and electronic units, this increases the operational capability for both soldiers and the vehicle. The TMS consists of an Air Handling Unit (AHU) and a Vapor Compression System Unit (VCSU) capable of providing 7.5 Kilowatts of cooling capacity for the crew and Line Repairable Units (LRUs). The AHU is mounted in the turret bustle and the VCSU is mounted forward of the Gunner's Primary Sight (GPS). The TMS uses enviromentally friendly R134a refrigerant and propylene glycol/water mixture to maintain the LRU touch temperature at less than 140 degrees Fahrenheit. The TMS is mounted in the left side of turret bussel and weighs 384 pounds.

The Army requires that all systems operate in the Army Common Operating Environment (ACOE) to improve combined arms operations. Digitization and information dominance across the entire Army for tactical elements is accomplished using Force XXI Battle Command for Brigade and Below (FBCB2) software. In Abrams, FBCB2 software is hosted on a separate card that enables situational awareness across the entire spectrum of tactical operation. It improves message flow, through 34 joint variable message formats, reports ranging from contact reports to logistic roll ups, as well as automatically providing vehicle location to friendly systems. The SEP allows for digital data dissemination with improved ability to optimize information based operations and maintain a relevant common picture while executing Force XXI full dimensional operation. This enhancement increases capability to control the battlefield tempo while improving lethality and survivability. Finally to ensure crew proficiency is maintained, each Armor Battalion is fielded an improved Advanced Gunnery Training System (AGTS) with state-of-the-art graphics.

Changes to the M1A2 Abrams Tank contained in the System Enhancement Program (SEP) and "M1A2 Tank FY 2000" configuration are intended to improve lethality, survivability, mobility, sustainability and provide increased situational awareness and command & control enhancements necessary to provide information superiority to the dominant maneuver force. The Abrams Tank and the Bradley Fighting Vehicle are two central components of the dominant maneuver digital force. System Enhancement Program upgrades are intended to:Additional weight reduction, embedded battle command, survivability enhancement, signature management, safety improvement, and product upgrade modifications to the M1A2 will comprise the "M1A2 Tank FY 2000" configuration fielded to units of the digital division beginning in FY 2000. The M1A2 IOT&E was conducted from September-December 1993 at Fort Hood, TX and consisted of a gunnery phase and a maneuver phase. The Director determined that the test was adequate, the M1A2 was operationally effective, but not operationally suitable and unsafe. That assessment was based on poor availability and reliability of the tank, instances of the uncommanded tube and turret movement, inadvertent .50 caliber machine gun firing, and hot surfaces which caused contact burns. FOT&E #1 was conducted in September-October 1995 in conjunction with the New Equipment Training for two battalion sized units. Despite assurances from the Army that all corrective actions were applied, numerous instances of uncommanded tube and turret movement, Commander's Independent Display (CID) lockup and contact burns continued during FOT&E #1. The follow-on test was placed on hold and the Army "deadlined" the two battalions of M1A2 tanks at Fort Hood for safety reasons. The PM isolated 30 "root causes" of the safety problems and completed hardware and software upgrades in June 1996 which were assessed in FOT&E #2. The M1A2 TEMP was approved during 2QFY98. This TEMP includes a coordinated plan for FOT&E #3 of the M1A2 in conjunction with the IOT&E of the Bradley Fighting Vehicle in FY99 at Fort Hood, TX. This combined operational test will consist of 16 force-on-force battles between a Bradley Fighting Vehicle System-A3/M1A2 SEP combined arms team and M1A1/ Bradley-ODS combined arms team. Additionally, it will serve as the operational test for the 2d Generation FLIR. This approach implements the Secretary of Defense theme of combining testing in order to save resources and ensure a more realistic operational environment. The Army and DOT&E completed vulnerability assessment efforts and concluded that the "M1A2 Tank FY 2000" is a significant change from the original M1A2 design and will require a system-level survivability evaluation. This evaluation will rely on full-up system level testing of two systems, component and sub-system level testing, modeling and simulation, existing data, and previous testing to assess susceptibility and vulnerability of the "M1A2 Tank FY 2000" and its crew to the expected threat and to assess battle damage repair capabilities. The M1A2 Abrams Tank with the corrective actions applied by the Program Manager during FY96 is assessed to be operationally effective and suitable. The availability, reliability, fuel consumption, and safety problems observed in previous testing have been corrected. FOT&E #2 was adequately conducted in accordance with approved test plans and the Abrams TEMP. There were no observed instances of the uncommanded tube and turret movement, inadvertent .50 caliber machine gun firing, and hot surfaces which caused contact burns in previous testing. The largest area of technical risk to the program is the development of the Embedded Battle Command software which is intended to provide friendly and enemy situational awareness and shared command & control information throughout the combined arms team. This software is being developed as a Horizontal Technology Insertion program and will be provided to the weapon systems and C2 nodes of the combined arms team in FY00. This development schedule is high risk and could adversely impact the M1A2 schedule.

- improve target detection, recognition and identification with the addition of two 2nd generation FLIRs.

- incorporate an under armor auxiliary power unit to power the tank and sensor suites.

- incorporate a thermal management system to provide crew and electronics cooling.

- increase memory and processor speeds and provide full color map capability.

- provide compatibility with the Army Command and Control Architecture to ensure the ability to share command & control and situational awareness with all components of the combined arms team.

Operations and Support

While the M1A2 SEP and M1A1D provide improved combat capabilities overmatch; the Army is working to improve reliability, reduce logistical footprint, and lower Operations and Support [O&S] costs for the tank. This effort is focused on two initiatives that provide the force with the biggest "bang for the buck" in terms of O&S cost reduction, readiness improvement, and sustainment of combat overmatch. These initiatives include the following Abrams Engine Campaign and the Abrams Integrated Management Overhaul Program (AIM):

. The AGT 1500 engine has served the Abrams tank well. It afforded a significant combat edge due to its lightweight, power, and stealth. However, the AGT 1500 is getting old and the fleet faces problems in maintaining this workhorse. The AGT 1500 represents 1960s technology and has been out of production since 1992. Declining reliability causes the engine to account for around 64% of the Abrams tank reparable O&S costs. The Army is focusing on the engine as a major element in easing the maintenance burden for the force while substantially reducing O&S costs.

PM Abrams has developed a two-phased program to improve engine readiness and lower costs. The first phase makes innovative use of a partnership with PM/AMC/industry to overhaul the existing AGT 1500 engine/components. This program is termed PROSE (Partnership for Reduced O&S Costs, Engine). Under PROSE, the government will "team" with the original equipment manufacturer to reengineer the production process and improve field support. The contractor provides quality parts and expert technical support, and the government (our depots) provides the skilled labor and facilities.

The second phase of the engine initiative involves replacing the AGT 1500 engine with a new engine. There is great potential for improved tank readiness and long term O&S cost reduction in the implementation of this phase. This approach will not be cheap and will require a major decision by the Army. A 2 billion-dollar investment is required to replace the current engine with a new engine in the active component along, with a potential savings of 13 billion over the remaining life of the tank.

The PROSE process is expected to improve reliability by 30%. The benefits of the new engine are much more dramatic - the Army could achieve a 4-5 fold improvement in reliability, hopefully a 35% reduction in fuel consumption, a 42% reduction in the number of parts, and a 15-20% improvement in vehicle mobility. Life cycle engine O&S costs are projected to drop from 16 billion dollars over 30 years with the current engine to 3 billion dollars with the new engine.

The second piece of our O&S cost reduction strategy is the Abrams Integrated Management (AIM) program. The AIM process overhauls an old M1A1 tank to original factory standards, applying all applicable MWO’s. The AIM Proof of Principle was completed in 1997, proving the cost-effectiveness of the concept and helping to define the scope. The AIM tank demonstrated an 18% O&S cost savings when compared to non-AIM tanks. The AIM overhaul concept is a cost-effective solution to address the problems of rising tank sustainment costs and increasing readiness concerns.