In recent months, we’ve seen much of these decades’ worth of progress erased. Contracts for evaluations of government programs were canceled, FFRDCs have been forced to lay off staff, and federal advisory committees have been disbanded.

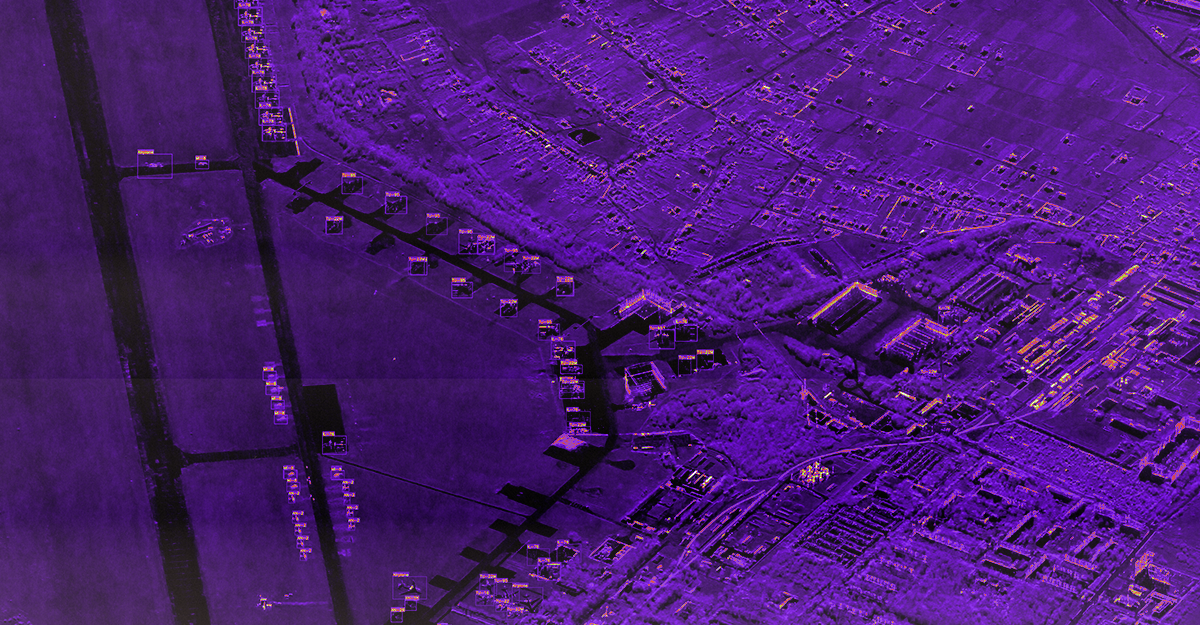

This report outlines a framework relying on “Cooperative Technical Means” for effective arms control verification based on remote sensing, avoiding on-site inspections but maintaining a level of transparency that allows for immediate detection of changes in nuclear posture or a significant build-up above agreed limits.

At a recent workshop, we explored the nature of trust in specific government functions, the risk and implications of breaking trust in those systems, and how we’d known we were getting close to specific trust breaking points.

tudents in the 21st century need strong critical thinking skills like reasoning, questioning, and problem-solving, before they can meaningfully engage with more advanced domains like digital, data, or AI literacy.